Well after getting Matilda back home from "Jules and Burts" place at Springwood up the Blue Mountains .

I spent a few days just walking around it pushing and poking at things that needed a tidy up and then sorting them in order of "Need to do" Nice to do".

So... No:1 priority on the Need to do list was the roof hatch.

A lot of the vans I have owned have had problems with the timber in the frame of the hatch... usually because the manufacturer didn't bother giving the timber ( usually softwood ) a good coat of oil based primer and oil based top coat(s). It appears "Fairway" where guilty of the same offence.

The 40mm X 19mm frame had rotted on a couple of the corners .

So.. off came the hatch ..

Soon became obvious that it would be quicker and better to simply build another hatch....so.. tossed the old one...

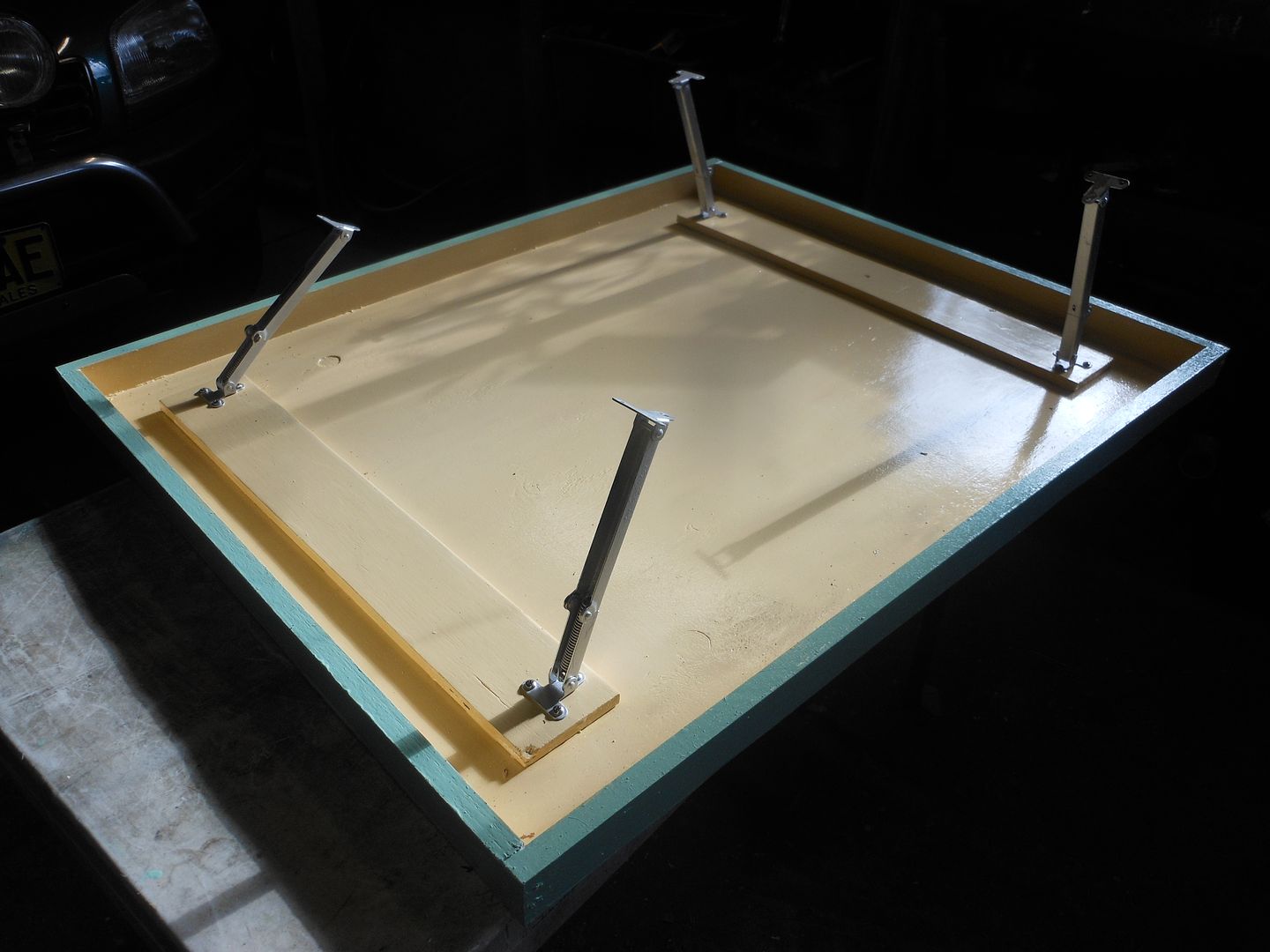

Set about building the new one. Glued and screwed all the corners together. I used 40mm X8G External decking galv screws and Liquid nails. Nice easy carpentry job...

2 coats of Taubmans primer sealer undercoat and leave it overnight.

Next day 2 coast of Dulux "Birdseed" .. it has become a Reddo fleet colour..... on the inside .. let dry .. then 2 coats of another Fleet colour Dulux "Eau-De-Nil".. let dry.

While the hatch was drying I moved onto another "need to do" jog.

Scrubbing the cupboard doors with liquid Ajax gel.... I had tried using car polish to cut the muck off the doors .. with little effect. So , Trish arrived on the scene with the Ajax... bloody bewdy I thought.. she is going to do some scrubbing, While I was talking to her with my back turned ,she made good her escape... leaving me to spend the next 3 hours scrubbing doors and walls...

You can see the difference on these two doors.. Right side untouched

left side done .. right side looked to be a problem.. that ink stain has been there since I bought the van back in 2006... petrol wouldn't move the stain.. Ajax did

By the end of the day I had the cupboard doors and surrounds shining like a new pin..

Feeling chuffed with the progress I collapsed to the floor.. Trish arrived with a bucket of warm water and a scrubbing/ scour pad.. again I thought she was going to get involved.. again I was let down.. so .. back in I went on hands and knees and gave the floor a scrub. I remember giving the van a good mopping and air out after it had 100mm of water through it back in the 2007 Newcastle floods.

Never did get the lino looking fresh.. so .. here was my chance to try and brighten things up...

Half the lino is in reasonable condition .. but is "Tesselated" near the entry... in other words it has cracked up into small 1" squares .. but still holding to the matting on the back of the lino. Too good to tear up.. but a bit shabby to look at...an hour or so saw it as good as its going to be..

Finished off the day putting the hinges back on the hatch which by now had dried out nicely..

Just have to fit the pull down handles and refit it to the van tomorrow. Then will need to get the engineers from the shed of invention in to look at a secure way of holding the hatch shut when travelling.

Cheers

Reddo